A ratiometric technique is used to compare the response of the two components and determine the value of the resistor under test.įigure 1 The circuit shown enables accurate measurement of very low resistance values by applying a low duty cycle pulse to the unknown resistor and a reference resistor of a known value. The circuit shown in Figure 1 provides a solution to the problem by applying a low duty cycle pulse to the unknown resistor and a reference resistor of a known value. But even at these tolerances, accurate measurement of very low resistance values can be rather difficult, especially when a large current is involved. For these applications, a tolerance of about 10%-20% is quite sufficient. Located right in Charlotte's backyard, the new distribution center in the city of Cornelius houses all baseline chassis components which are made available for purchase.Maybe the most common applications for very-low-value resistors (i.e., milliohms (mΩ) and below) are current-controlling circuits, where their low value reduces power losses. has recently opened a distribution center in North Carolina. We look forward to working with you on your next project.

#Technique engineering inc series#

No matter what kind of car you find yourself driving or what racing series you compete in, if you want premier engineered chassis components for your high performance racing machines, talk to us.

#Technique engineering inc pro#

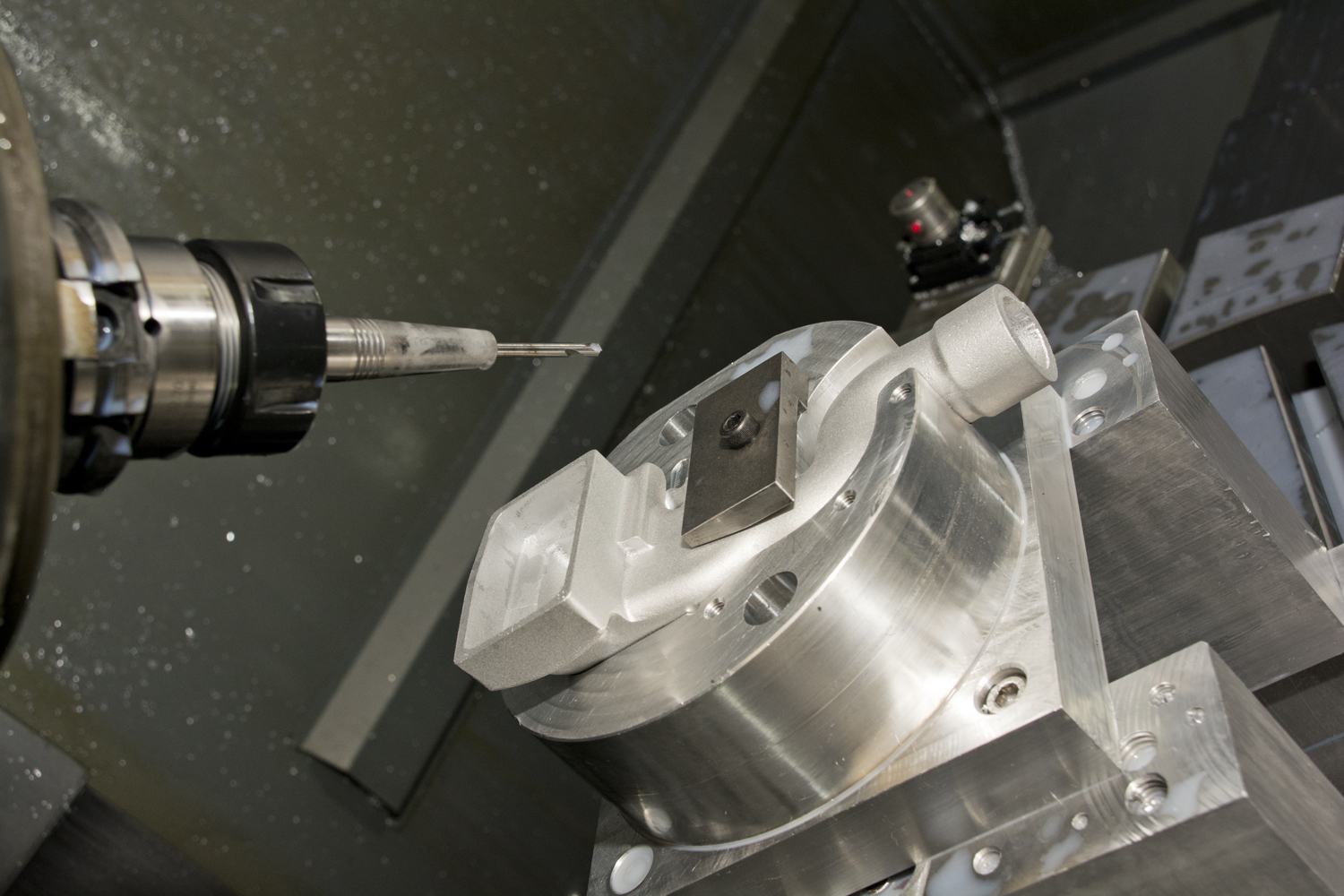

Technique Engineered Chassis Components are produced from the finest quality materials and preformed with laser-guided precision to fit four of the NHRA's® largest classes-Top Fuel, Funny Car, Pro Stock and Pro Stock Motorcycle.

They can be created with or without holes at your team's request.īy applying the same championship processes that produce our NASCAR® chassis components, we are able to deliver the precision and consistency needed to build some of the fastest racing machines on the planet. We manufacture our bumper bars and splitter bars as a one piece formed tube. All intrusion plates meet NASCAR® specifications. They are preformed to layup and weld, allowing for extremely easy installation.

We use dedicated tooling and optimum material thickness to create our intrusion plates. Our trailing arm assemblies are developed to meet each team's chassis configuration and follow all NASCAR® specifications. All spring buckets comply with NASCAR® standards. Custom hole patterns are utilized to meet your team's unique configuration. They are deep-drawn, with a base thickness of. We create our spring buckets using 4130-grade steel.

All drive shaft tunnels are manufactured within the guidelines set by NASCAR®. Our drive shaft tunnels are created with specific preferences set by your team and designed to optimize access to the drive shaft. Custom-built chassis kits allow us to bend, cut, form and modify the chassis components to your particular standards while still meeting NASCAR® specifications.

Both kits adhere to NASCAR® standards and are manufactured with the same precision and excellence expected from Technique. We can provide your team with either baseline or custom-built chassis kits. Every component is also fully repeatable with impeccable accuracy. Custom ConfigurationsĮvery component we manufacture can be formed and modified to meet YOUR specific configurations, no exceptions. In fact, 70% of Sprint® Cup teams utilize Technique Engineered Chassis Components in their cars! It's our dedication to quality, precision and customer service that make us the fastest growing provider of chassis kits and components in NASCAR®. Technique has partnered with many of the winningest NASCAR® teams in the Sprint® Cup Series as the supplier of their chassis components. Our favorite color is checkered, and our teams see it often.

0 kommentar(er)

0 kommentar(er)